I recently came across a prominent architect professing his love on social media for polycarbonate sheets. He claimed them as a wonderful new material which is ‘revolutionising architecture’. While I respect him a lot for his creativity, i found his review is one-sided, focussing only on the positives. Perhaps it is sponsored or supported by a polycarbonate manufacturer.

Traditionally architects only discuss materials for their performance, independently of manufactures. Afterall, influencing the next generation of young architects on social media must come with greater responsibility of highlighting the negatives as well.

My intentions here is not to be controversial but present a more balanced viewpoint on polycarbonate sheets.

The main positives of Polycarbonate sheets, as highlighted on this video in social media are below. I express my reactions in brackets.

- Good for Daylight ( Maybe or Maybe not )

- Excellent Thermal Insulation ( Relative to what ? )

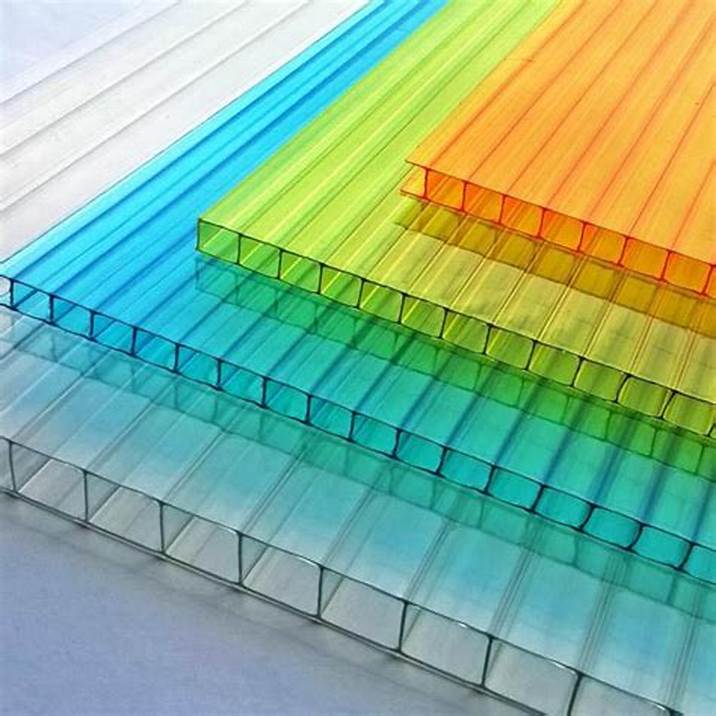

- Visually Stunning – ( Ok, Thats a personal opinion)

- Design flexibility as they are Easy to Bend and Cut. ( True, its easy to use but is it better ? )

- Ability to resist yellowing and degradation over time, UV resistant ( Only with UV coatings for longer time, typically becomes yellow with time and degrades )

Above positive qualities make polycarbonates a ‘go to choice’ for architects as per the video.

I will now try to highlight some issues with polycarbonate, while also trying to compare it to glass. This is pertinent because usually for architects ‘polycarbonate is the cheap alternative to glass’.

1- Polycarbonate ( building grade ) allows daylight but doesn’t have the optical clarity of glass. Infact, that’s why most polycarbonates are made for diffusing daylight which means much lesser amounts of total Visible Light Transmission happens indoors as compared to glass. So it’s not better for daylighting than glass.

2- Typically double layered polycarbonate sheets provide more heat insulation than a single untreated glass pane, but it’s important to note that glass has become very high tech with numerous coatings and layers available. Typical Double and Triple glass will outperform polycarbonate sheets in Thermal Insulation. So for energy efficiency of regularly air-conditioned spaces like office, Double layered glass would offer more energy efficiency.

3- Glass is transparent to UV. UV exposure should be reduced, as we know. Polycarbonate cuts UV since it cuts daylight in general. Polycarbonates need additional coatings to increase UV protection. Glass too can do this as well. Remember many of us use anti-UV coated eyeglasses.

4- Glass shatters and hence the appeal of polycarbonate which doesn’t break easily. However, polycarbonate sheets are prone to scratches which decrease their visual appeal long term.

Now, lets highlight some sustainability and health issues which should also be considered while selecting materials :

5- Embodied Carbon: Both materials both Polycarbonate and Glass have significant embodied energy, as they require to burn fossils fuels to make them. Let’s not debate which has more since it is a complex topic which requires evaluation of Life Cycle of both materials specific to a project site.

6- Recyclability : Both materials are non-biodegradable, but glass has excellent recyclability, better than polycarbonate. Which mean glass can be used over and over again. Glass industry is also more advanced and recycling is happening more today making glass more sustainable. Polycarbonate recycling is tougher and not that well supported as yet by Industry.

7- Inertness : Glass is a totally inert material. So if it goes into a landfill ( or remains in your room ) it will not release any harmful chemicals. However, certain Polycarbonates much like other plastics will release harmful chemicals into the soil polluting the ecosystems. Exposure to high temperatures or sun may actually make polycarbonate sheets release these chemicals.

8- Previously 100% of polycarbonates, ( now some of the Polycarbonates still ) release a chemical called BPA on degradation which has been linked to Cancer. While some manufacturers claim BPA-free products, their process must be third party verified before using, to protect occupants especially when used in large quantities in any space.

Hope above gives you a more holistic and balanced picture about polycarbonate as a material. Maybe you will agree that its not that revolutionary.

So, which is better Polycarbonate or Glass ? I would personally recommend below approach :

- Do not replace glass with Polycarbonate just for aesthetics.

- Use polycarbonates in smaller quantities to decrease after use impacts on ecosystem.

- Don’t expose polycarbonates to extreme temperatures or solar loads.

- Provide abundant ventilation in occupied spaces which use polycarbonate sheets, or other plastic materials to minimize impacts on occupant health.

- Look to buy from manufacturers that can assure BPA free products and promise recycling facilities.

Author : Harsh Thapar

Notes:

( FYI – BPA release is also associated with certain paints, finishes used inside buildings and research on this aspect is emerging.

https://www.sciencenews.org/blog/science-the-public/when-bpa-free-isnt

Just google to find lots of papers and articles on BPA and its health impacts.)